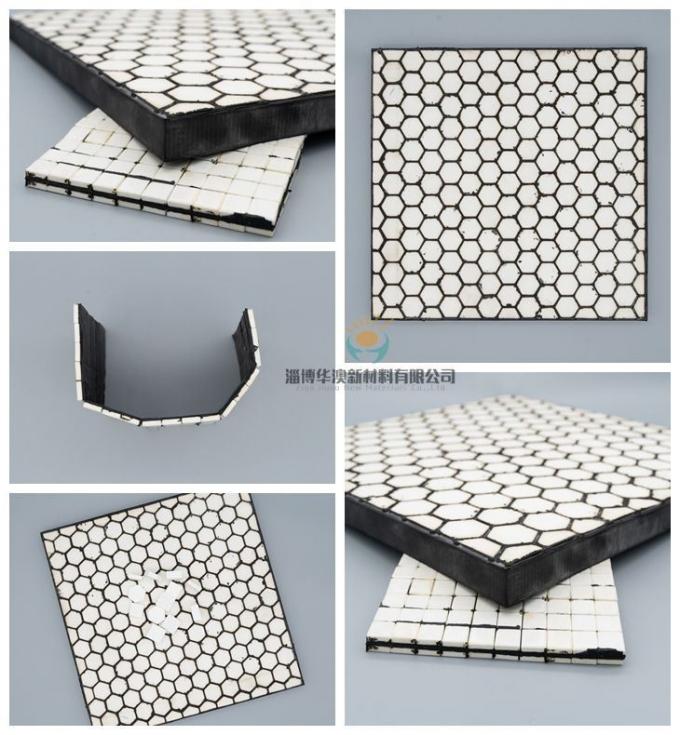

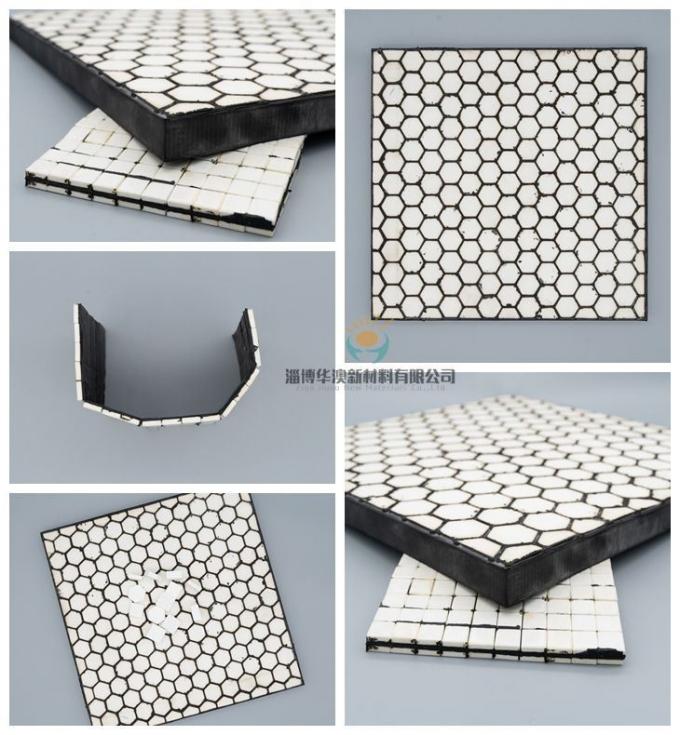

Rubber Backed Ceramic Wear Plates

Alumina ceramic liner has excellent abrasion resistance,impact resistant,corrosion resistance, heat resistance,it is widely used in the mining,mineral process, power generation plant,steel plant,cement industries, petro-chemical refining, coal washery, port .Common items equipment need wear linings are: Agitators, Bends, Branches, bunker, Chutes, Classifiers, Cones, Cyclones, convey belt, Distribution, Ejectors, Fans, Feeders, Hopper, Launders, Manifolds, Mills, Orifice, Pipes, Pipe Bends, Pipe fitting, Spoons, Square Bends, Square to Round,Tanks, Troughs, Transfer points; T-Pieces, Y-Pieces etc.

Not only professional producing alumina industrial ceramics, our team also can help the client to choose the right product and afford the drawings for the pre-engineered tiles, designed layout drawing.

1.92%Al2O3 & 95% Al2O3 Standard wear resistant alumina ceramic liner/cylinder/mosaic/hexagon tile/ceramic cubes.

2.Abrasion resistant high alumina ceramic pipe/tubes ,diameter from 20mm to 500mm

3.Ceramic rubber wear liner/Steel Rubber ceramic composite panel.

4.Wear resistant pre-engineering tile in a variety of geometric shapes from simple to complex

5.Ceramic lined process equipment like pipes,,bends,chutes,hoppers,bunkers, cyclones,etc.

|

Application

|

Fastening Methods

|

|

Backing Plates

|

|

Raw Material Feed

|

Rubber Bond

|

Plain Rubber with Captive Studs

|

|

|

Head Chute Liner

|

Studs

|

Mild Steel

|

|

|

Impact Curtains

|

Captive Socket

|

3 Cr12

|

|

|

Chute Liner

|

Plug Weld

|

Stainless Steel

|

|

|

Rock Boxes

|

|

|

|

|

Skirt Boards

|

|

|

|

|

Bucket Liner

|

|

|

|

| |

|

|

|

| Item |

Index |

| Content of alumina |

95% or 92% available |

| Denisty |

≥ 3.6g/cm3 |

| Rockwell hardness |

≥ 80 HRA |

| Impact strength |

≥ 850 Mpa |

| Fracture toughness |

≥ 4.8 Mpa . m½ |

| Bending strenght |

≥290 Mpa |

| Thermal conductivity |

20 W/ M. K |

| Thermal expansion coefficient |

7.2 * 10-6M/M.K

|

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!